Whether it’s through installing automated storage and retrieval systems (ASRS), advanced picking and handling systems, or cutting-edge sorting solutions, we’re committed to tailoring a strategy that fits your unique business needs and objectives. Looking to drive efficiency in your workspace? Talk to the experts at Unistor about how automation can help take your operation to new heights.

Warehouse Automation

Embrace the future of warehousing with Unistor. We can help your business integrate automation, robotics, and innovative technologies to empower your warehouse to exceed its targets and drive operational efficiencies.

Take Your Warehouse to the Next Level

Driving Efficiency with Automation in Warehousing

Warehousing can be a complex process, with room for human error and inefficiencies. Unistor can help you transform these challenges into opportunities by integrating automation technologies into your operations. Through automation, you can eliminate labour-intensive tasks that involve repetitive manual work, lower resource demands, and fine-tune processes, leading to heightened efficiency, reliability and productivity. The result? A lean, agile supply chain and a more profitable business operation.

Benefits of Warehouse Automation

Investing in warehouse automation with Unistor can provide countless benefits:

Types of Warehouse Automation

Warehouse automation ranges from software solutions replacing manual tasks to advanced, AI-powered robotics to boost operational efficiency. Invest in a robust Warehouse Management System (WMS) for real-time data and inventory control, or Goods-to-Person technologies like carousels and vertical lift systems, to increase picking speed. Automated Storage and Retrieval Systems (AS/RS) and Automatic Guided Vehicles (AGVs) streamline material storage and movement, whereas Automated Sortation Systems leverage digital technology to reduce errors and increase efficiency.

Enquire now

Creating Automated Systems Tailored to Your Operations

Unistor takes pride in creating customised automation solutions to meet your unique operational needs. Whether you need a complex ASRS or an AI-powered picking and sorting system, we partner with top-tier suppliers to develop an automation strategy that brings total efficiency to your warehouse. While these technologies have an upfront cost — their immediate benefits, such as improved operations, reduced human error, and increased efficiency, make them a smart investment.

Investing in Efficiency

Investing in warehouse automation can require significant capital, but the long-term returns are undeniable. Automation translates into heightened productivity, lower labour expenses, and superior operational efficiency—factors that contribute directly to your bottom line. This isn't merely an investment in a system; it's a strategic move towards a sustainable and scalable business model. Eager to understand how automation can take operations to new heights? Reach out to our experts today and unlock the transformative power of advanced warehouse automation for your business.

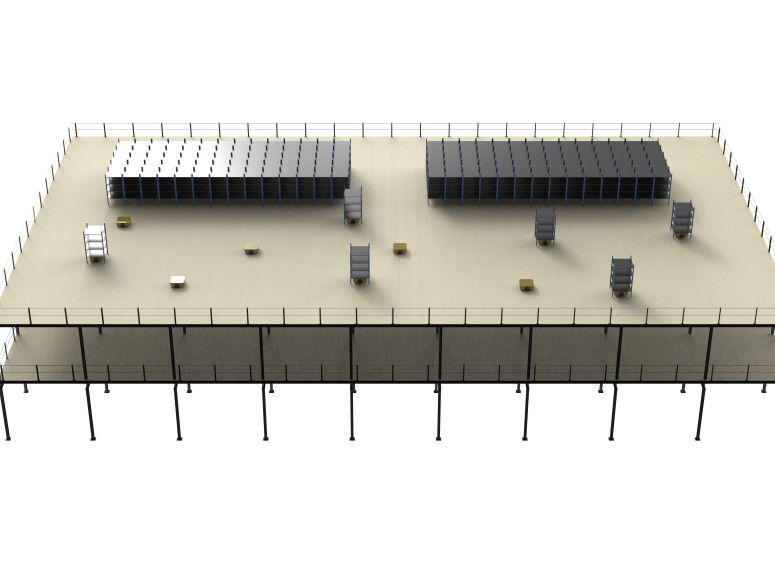

Double The Floor Space In Your Warehouse

Frequently Asked Questions

ASRS, or Automated Storage and Retrieval System, in a warehouse refers to high-speed automation solutions that streamline storage and retrieval processes. As your strategic partner, Unistor can help you integrate ASRS solutions to enhance space efficiency, improve accuracy, and drive productivity, enhancing your warehouse operations for a more profitable outcome.

ASRS, or Automated Storage and Retrieval Systems, use robotic arms or cranes to retrieve items. In contrast, Shuttle Systems utilise autonomous carts that move along racking to pick items. Unistor designs solutions incorporating both, crafting custom automation strategies to maximise warehouse efficiency, productivity, and return on investment.

The three levels of warehouse automation are manual warehouses with software support, mechanised warehouses employing automated equipment, and advanced warehouses harnessing AI and robotics. Unistor specialises in customising solutions across these levels,

optimising your warehouse operations for enhanced efficiency, profitability, and scalability.

Yes, a warehouse can be fully automated. Leveraging technologies like AI, robotics, and advanced software can replace manual tasks, driving efficiency and accuracy. While full automation requires investment, the long-term ROI is substantial, streamlining operations and empowering scalable growth in a competitive commercial landscape.

Robotics in warehouse automation is transforming the logistics sector. Robots automate tasks such as picking, sorting, and transporting goods within warehouses. This ensures enhanced efficiency, fewer errors, and consistent 24/7 operations. As AI-driven robots become more advanced, they continuously refine and scale warehouse processes, solidifying their pivotal role in logistics optimisation.