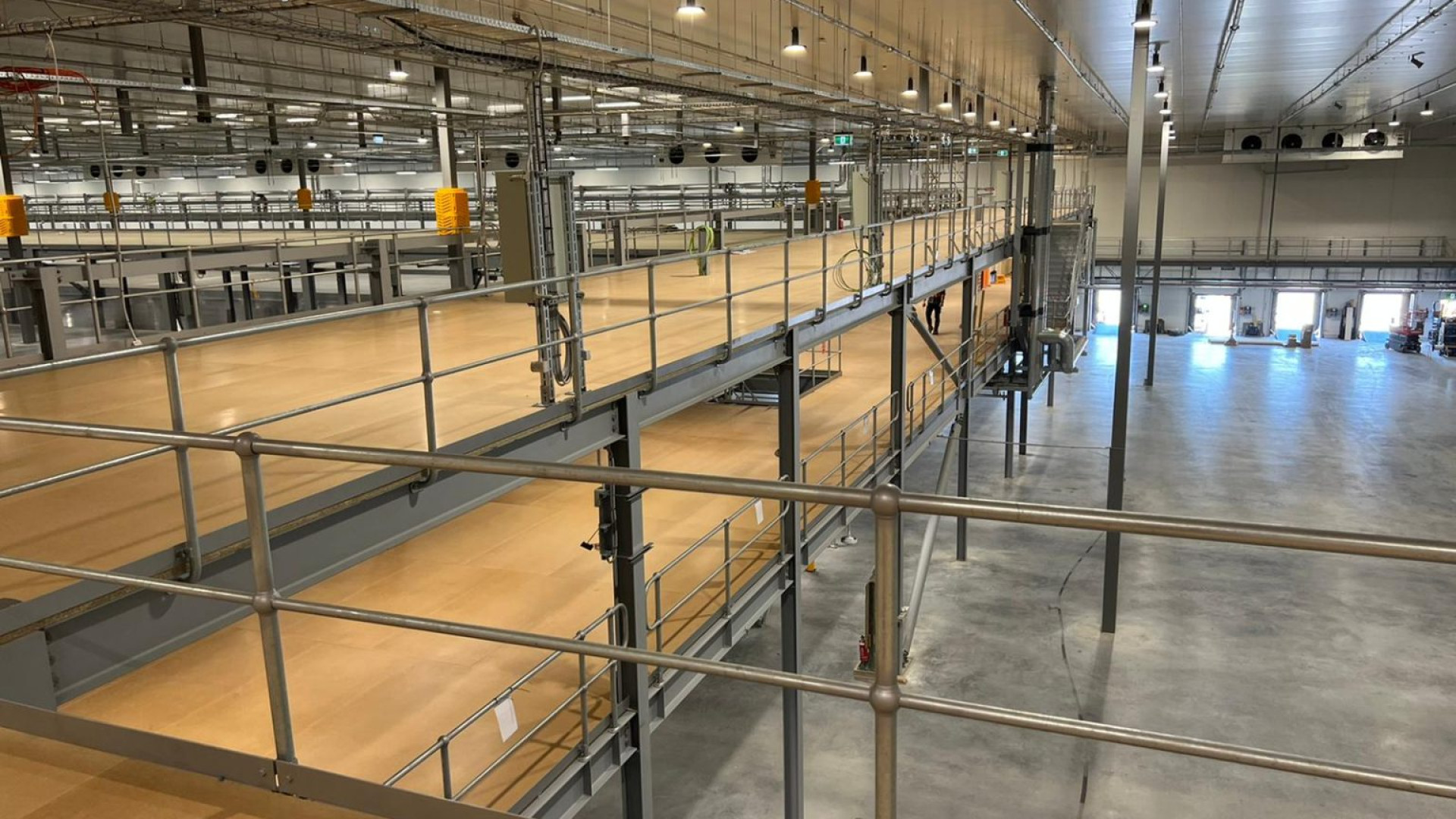

Mezzanine flooring systems have been part of industrial and warehouse architecture for years, offering an additional layer of storage space without the need for an entirely new building. But with the modern warehouse evolving at an unprecedented rate, technology like Automated Guided Vehicles (AGVs) have become must-haves. What does this mean for your mezzanine design? Think of adaptability and automated integration. Unistor, as Australia’s leading manufacturer and supplier of mezzanine solutions, is at the forefront of this change, ensuring that AGV warehouses are fully supported with the best mezzanine systems available. Read on to discover how you can take your AGV warehouse to the next level.

Mezzanines and AGVs: The Ideal Match

Mezzanines are intermediate floors constructed in between the main floors of a building, effectively utilising vertical space. When built in warehouses, they can double or even triple the storage capacity without expanding the building’s footprint. AGVs, on the other hand, are mobile robots used in warehouses to transport goods without human intervention. They follow markers or wires in the floor, or use vision, magnets, or lasers for navigation. When these two modern solutions meet, the result is a stunning blend of space utilisation and workflow efficiency.

Why Integrate a Mezzanine System with AGV Operations?

Integrating AGVs with mezzanine systems is not an afterthought—it’s a pivotal consideration right from the get-go. At the design phase of a mezzanine project, careful planning is required to ensure that the layout, weight capacity, pathways, and safety barriers are best suited for AGV operations. The idea is simple: we want to make sure the added vertical space from the mezzanine works perfectly with the advanced automation and movement capabilities of AGVs.

The Advantages of the Mezzanine-AGV Integration

Pairing your mezzanine system with AGVs is like a match made in logistics heaven. Think of it as giving AGVs an extra work area, allowing them to move and work in more directions and spaces. This synergy doesn’t just offer one or two benefits—it transforms the whole warehousing game. Let’s take a look at the specific advantages this integration brings:

- Enhanced Productivity: Speed is of the essence in logistics. With AGVs operating on mezzanines, goods can be transported faster, reducing bottlenecks and ensuring timely deliveries.

- Maximised Space Utilisation: Warehouses can often suffer from space constraints, limiting their capacity to stock goods. Mezzanines allow for better vertical space usage, ensuring every inch of the warehouse is effectively utilised by your AGVs.

- Cost Savings: Investing in a mezzanine system might seem like an initial cost, but the ROI is substantial. With more space to store goods and streamlined operations, you can massively save on external storage costs and improve inventory management.

- Streamlined Logistics: AGVs programmed to operate on mezzanines can sort, pick, and place goods more effectively. They can be scheduled for off-peak hours, ensuring 24/7 operations without fatigue.

- Safety & Accuracy: Human errors can lead to misplacements, losses, or even accidents. AGVs are precise and can operate safely in well-structured mezzanine systems.

- Scalability: As businesses grow, so do their warehousing needs. With a mezzanine system, expansion becomes vertically possible. Plus, integrating more AGVs into your existing system is a breeze.

Mezzanine Flooring for AGVs

AGVs navigate using technology like lasers, magnets, cameras, and sensors. While some follow paths set by magnetic tapes or wires embedded in the floor, others use visual markers or GPS systems. Regardless of their guidance method, for AGVs to function optimally on mezzanine floors, selecting the appropriate flooring is essential. Here are some key considerations:

- Traction Matters: Avoid surfaces that are too slick. The flooring needs grip to allow AGVs and AMRs to move efficiently and safely.

- Smooth Surfaces: Uneven floors, like cracked concrete, can damage these vehicles. Smoothness reduces maintenance costs and extends their life.

- Matte Over Shine: Shiny surfaces might reflect lasers and disrupt AGV navigation. A matte finish is preferable.

Unistor ensures your mezzanine surface is just right, balancing automation needs with capacity and safety requirements.

Unistor’s Approach to AGV Mezzanine Solutions

At Unistor, we understand the ins and outs of AGV operations and the challenges they present. We have crafted mezzanine solutions that not only support, but will also enhance automated operations. Our approach is underpinned by adaptability: each design is customised to the specific needs of your AGV-driven warehouse, with smooth integration and optimal performance. Here’s how we’ve innovated our mezzanine solutions to pair perfectly with AGV warehouses:

- Robust Materials: We use only the highest quality, 100% Australian-made materials to ensure that our mezzanines can handle the increased weight and high traffic flow of AGVs.

- Intelligent Design: By collaborating with AGV manufacturers and warehouse operators, we’ve developed designs that allow for smooth AGV movement, including gentle inclines, wider lanes, and clear markings.

- Integrated Safety: Safety remains a top priority. Our range of mezzanine systems incorporate barriers, guardrails, and safety sensors that are compatible with AGV operations.

- Customised Solutions: No two AGV warehouses are the same. At Unistor, we offer bespoke mezzanine solutions tailored to the specific needs of each warehouse, ensuring optimal performance and efficiency.

Future-Proofing with Unistor

With the rapid automation of warehousing technologies, it’s essential to invest in infrastructure that’s not just suitable for today but also adaptable for tomorrow. As Australia’s leading manufacturer and supplier of mezzanine floors, Unistor’s solutions are AGV-ready and designed with the future in mind. We’re here to help you maximise space, optimise operations, and ensure that your business will thrive in today’s competitive landscape.

Whether you’re planning on building a new mezzanine system for an AGV warehouse or looking to upgrade an existing one, our team at Unistor has the expertise and the commitment to deliver the best solutions. Talk to us today about tailoring a mezzanine solution that aligns with your business goals.

Choose Unistor as the right mezzanine solution and increase your storage capacity by double.